Ship component

production

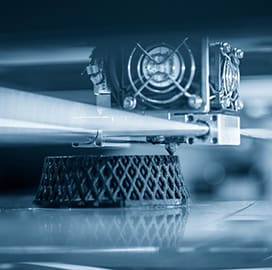

Additive Manufacturing System Enables Repairs on USS Bataan

USS Bataan crew members have produced a component using an onboard hybrid 3D printer to repair the ship’s ballasting system.

Production and installation of the stainless steel sprayer plate took less than five days with support from Naval Sea Systems Command and APL.

Manufacturing the part at sea allowed the USS Bataan to avoid a costly return to port, Johns Hopkins Applied Physics Laboratory said.

The laboratory installed the hybrid manufacturing system on the USS Bataan in October 2022. According to APL, the system features directed energy deposition 3D-printing additive and subtractive manufacturing capabilities.

Craig Hughes, assistant program manager for expeditionary logistics in APL’s Force Projection Sector, said the ship’s crew used computer-aided design software to create a digital model of the steel sprayer plate. He explained that neither NAVSEA nor APL had the technical data package to produce the part yet.

Hughes added that the model was sent to the laboratory for testing and refinement using the Digital Manufacturing Environment, a system that can store and send NAVSEA-developed technical data packages to ships.

APL said it is working with the U.S. Navy to enhance the Digital Manufacturing Environment.

Category: Future Trends