Additive manufacturing

Argonne National Laboratory Develops AI for Finding Defects in 3D-Printed Parts

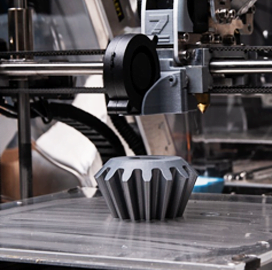

The Department of Energy’s Argonne National Laboratory has devised an artificial intelligence system meant to spot defects in metal parts produced with additive manufacturing.

Scientists from Argonne and the University of Virginia recently published a paper detailing how machine learning and imaging can be used to detect and predict pore formation in laser powder bed fusion, an AM process involving the molding of metal powder melted by a hot beam.

The study involved the use of high-intensity x-ray beams produced by the Advanced Photon Source, a Department of Energy Office of Science user facility at Argonne. Tao Sun, a UVA associate professor and research team lead, said that the APS enables “perfect prediction of pore generation” by enabling the collection of accurate thermal image data to be analyzed by a trained ML model.

He added that the AI system could generate a log file that pinpoints where defects could have occurred, potentially saving time and resources. According to Sun, the objective is to develop a capability that also identifies what a part’s flaw is and how it can be addressed, Argonne said Thursday.

Category: Federal Civilian