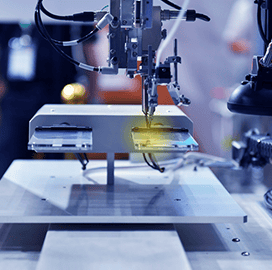

AI-aided manufacturing

NASA Uses AI-Assisted Design to Produce Mission Hardware

NASA has used artificial intelligence to design mission-specific hardware.

NASA research engineer Ryan McClelland designed what he called “evolved structures,” specialized, one-off parts. Their production involves work by computer-assisted design specialists as well as artificial intelligence. McClelland underscored the need for human intuition, noting that “algorithms do need a human eye.”

Manufacturing the parts could take up to two hours, NASA said.

The engineer also stated that the structures are around 67 percent lighter compared to traditional components, and they can be created by commercial vendors much faster than how NASA usually creates components. He added that parts are analyzed using NASA-standard validation software and processes to identify points of failure.

Peter Nagler, a physicist at the Goddard Space Flight Center, used evolved structures to help develop the EXoplanet Climate Infrared TElescope mission, which is used to study exoplanets orbiting other stars. McClelland used the AI process to create a titanium scaffold for the mission’s telescope, which can withstand extreme temperatures and conditions.

McClelland said NASA can benefit greatly from AI-assisted design as it can be used to make thousands of unique parts annually when paired with 3D printing.

The AI design and development initiative is supported by the Center Innovation Fund housed within NASA’s Space Technology Mission Directorate. Goddard’s Internal Research and Development program is also supporting the effort.

Category: Digital Modernization